Kwikstage Scaffolding

Tradex LLC > Kwikstage ScaffoldingKwikstage Access Scaffolding

TKwikstage is by far the most common system used today, it is based on the same bay size as Cuplock . Kwikstage uses a “wedge” and “V-pressing” to locate and lock all components together. Ledgers and transoms are fixed to the vertical standards using captive wedge connections, eliminating the need for transverse bracing. All Joints are self-locating. They have been designed for use by unskilled labour, keeping erection times and costs to a minimum. This ensures stringent safety levels can be easily achieved.

Kwikstate Access Scaffolding Process

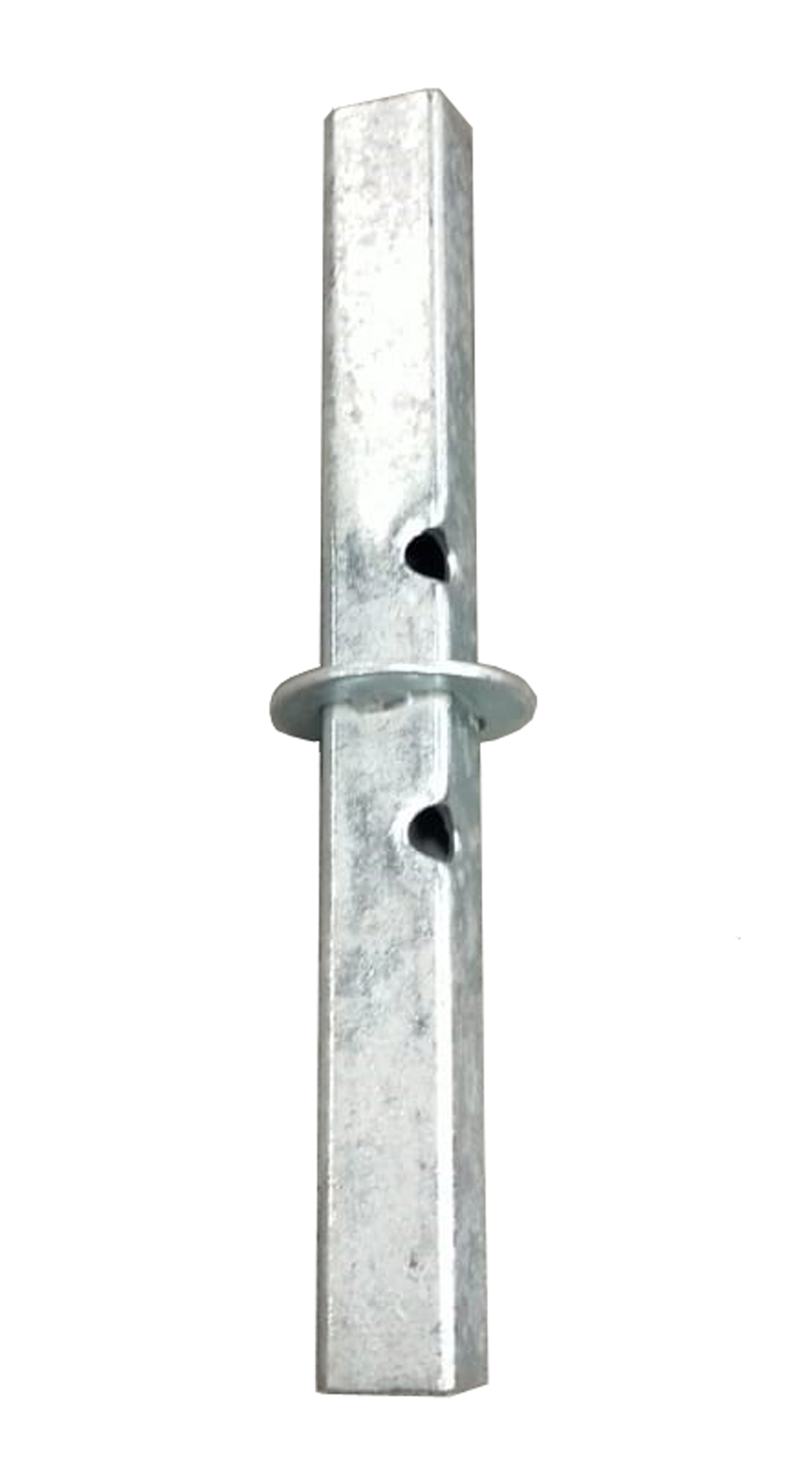

- 1. SPIGOT JACK (BASE JACK)

Spigot jack is inserted into an open-ended standard to locate the Kwikstage drophead. The maximum permissible axial load is spigot jack is 55KN.

Adjustable base jack is used at the bottom of the standard to provide an additional safe working height of 350mm.

CODE WEIGHT (KG) 450137 4.00 CODE WEIGHT(KG) 450137 4.00 - 2. KWIKSTAGE STANDARDS

3. LEDGERStandards are made from standard scaffolding tubes. They have V pressing welded at 495mm centre to provide 4-way connections for the kwikstage ledgers. Open ended or spigot standards are available.

Kwikstage Ledgers are used to fix the standards longitudinally. Ledgers are available in both imperial and metric sizes.

Code LENGTH WEIGHT (KG) 410110 8’0’’ 9.50 410113 6’0’’ 7.00 410116 4’0’’ 5.00 410119 3’0’’ 3.80 410122 2’0’’ 2.70 Code LENGTH WEIGHT (KG) 415155 2.40 9.40 415158 1.80 6.90 415164 1.20 4.90 415167 0.90 3.70 415170 0.60 2.65 - 4. SPIGOT CONNECTOR

The flanged spigot connectors are used to join open ended standards. And is used to fix a drop head on an open-end standard, where the top spigot jack is not required.

CODE WEIGHT (KG) 450189 1.00 - 5. DROPHEAD

Drophead supports the beams which are seated on the lipped support plate. To strike the drophead, rotate the collar and the support plate will allow the beams to be removed. The head plate remains in position supporting the concrete slab.

CODE LENGTH WEIGHT(KG) 410445 667MM 5.50 - 6. INFILL BEAM

Infill beams span between drop heads or between decking beams. Infill beams are spaced out at pre-determined centres to support the plywood.

CODE LENGTH WEIGHT(KG) 410216 4’0’’ 4.60 410219 3’0’’ 3.50 CODE LENGTH WEIGHT(KG) 415231 1.20 4.50 415232 0.90 3.40 - 7 SAFE WORKING LOADS KWIKSTAGE DECKING

The lightweight steel fabrication includes a 100mm wide top flange, which eliminates the necessity for a plywood infill, so cutting down maintenance cost. Heavy duty pressings are fitted to the beam ends ensuring adequate protection against site abuse. These incorporate a tongue location for the drophead.

CODE LENGTH WEIGHT(KG) 410216 4’0’’ 4.60 410219 3’0’’ 3.50 CODE LENGTH WEIGHT(KG) 415231 1.20 4.50 415232 0.90 3.40 LOADING

The system is designed to support a load of 40kn on any bay. This there-fore gives a maximum load on any supporting leg of 40kn. This can be equated to a slab thickness for the various grids normally obtainable from Kwikstage decking. This enables the load distribution to be derived to ensure individual beams are not over loaded.Grid size Concrete slab thickness (mm) 8’0’’x4’0’’(2.4x1.2) 455 8’0’’x6’0’’(2.4x1.8) 275 8’0’’x8’0’’(2.4x2.4) 185 6’0’’x4’0’’(1.8x1.2) 635 6’0’’x4’0’’(1.8x1.8) 395 4’0’’x4’0’’(1.2x1.2) 995 - SAFE WORKING LOADS KWIKSTAGE SUPPORT

DRID CENTERS OVER/ALL LENGTH (MM) DIMENSION A(MM) S.W.L (KN) (U.D.L) S.W.L (KN) POINT LOAD ON NODE (S) 8’0’’(2.4M) 2320 (2280) 630 40 10 6’0’’(108M) 1710(1680) 477 40 10 4’0’’(1.2M) 1100(1080) - 40 20

Tradex is a company which each and every customer are proud to belong, We are been trusted in our services across the globe.