Decking

Tradex LLC > FormworkCuplock Formwork with S150 Aluminium Beam

This system adopts the use of aluminium beam as primary and secondary beam as this system can resist high capacity of shear and moment forces. This is also advisable for reusable characteristics of the beams in other construction areas where supports are necessary.

The skilfulness of cuplock system enables it to be used in a wide range of access and formwork application from normal civil project to complex mechanical project. Cuplock system can be constructed and dismantled very quickly. All component is of standard length and all fittings are repositioned. This minimizes the need of skilled operatives. Each component interlocks with the other in such a way that ensures a positive connection.

Cuplock Procedures

- 1. BASE JACK

The Adjustable Base Jack is used at the bottom of cuplock formwork to provide an additional maximum adjustment of 500mm Permissible Axial load 57KN. - 2. CUPLOCK STANDARDS (SPIGOT CONNECTOR)

SPIGOT CONNECTORThe Cuplock standards are available to suit any propping or access application economically, the standards can be used for support or access as required. Standard are connected end-to-end by an internal spigot. A bolt is used to connect to the lower standard. Standards Spigot L (m) W (kg) L (m) WT (kg) 3.0 15.2 1.3 6.8 2.5 12.8 1.8 9.0 2.3 11.8 2.0 10.0 1.5 7.5 1.3 7.0 1.0 5.1 - 3. LEDGERS

Ledgers are available in a range of standard sizes or can be made to special length if required. L (m) W (kg) 2.5 9.3 1.8 6.8 1.6 6.1 1.3 5.0 1.2 4.7 1.0 4.0 0.9 3.6 0.6 2.5 - 4. FORKHEAD (U-Head)

For traditional timber, steel or aluminium beam support. U-head is structured to accommodate single and double timbers of 75mm nominal width. It is used with a universal jack to give height adjustable. - Primary & Secondary Layer

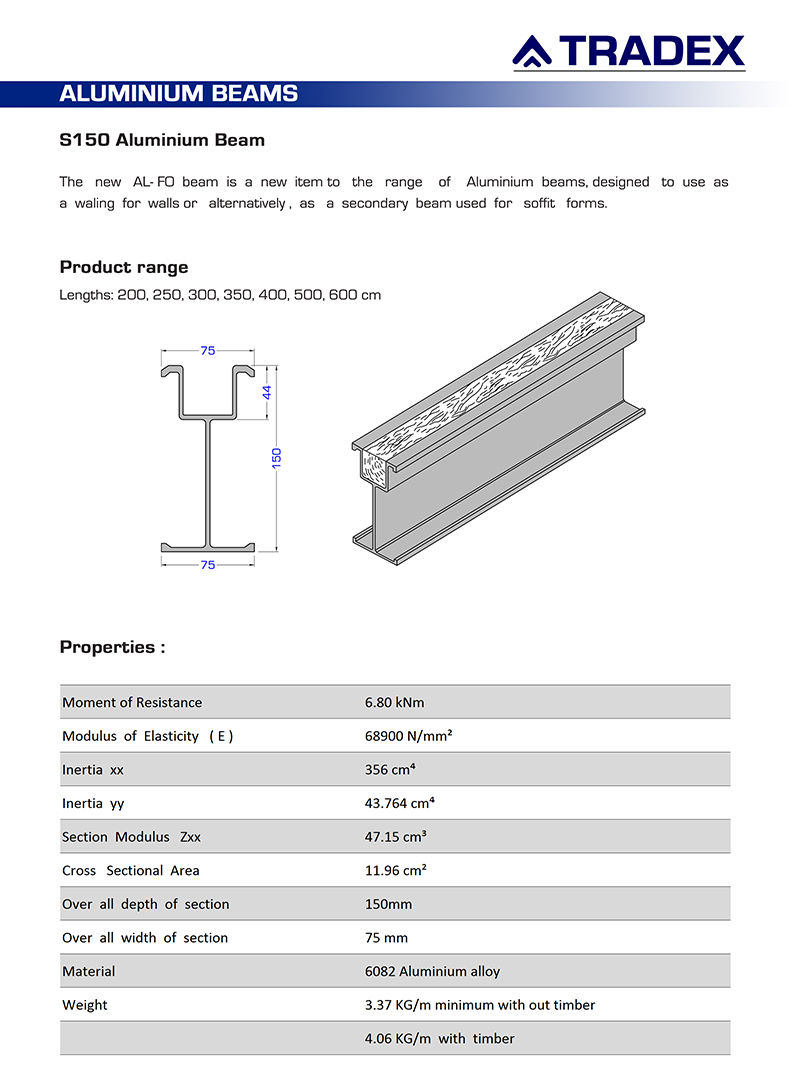

H20 Aluminium Beam